See what our Customers have to say....

Huntingdon Fusion Techniques HFT® have received

numerous letters of praise from users, many of them major

international manufacturers.

Here are some comments which have been received in

writing to give you an idea of the benefits others have

experienced using Techweld® MultiStrike®.

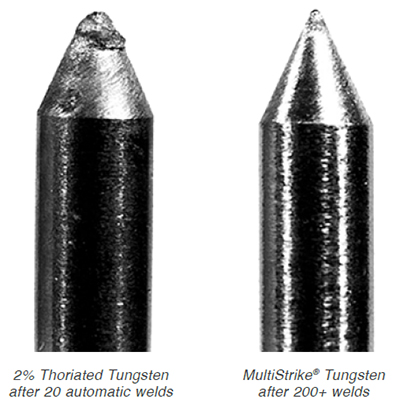

"We manufacture small pharmaceutical fittings

using manual TIG welding and produce tube-tube

joints using mechanised orbital welding. In both

applications we have observed a four to five time

improvement between re-grinding when replacing

thoriated tungsten with your MultiStrike®." New York,

USA.

"The number of arc strikes between re-sharpening is

considerably greater with MultiStrike® than with thoriated

electrodes. We also find the lower heat input is a benefit

since we often weld in very close proximity to glass."

Senior Production Engineer.

"The introduction of MultiStrike® has been welcomed

by all our welding staff. The new electrodes are giving

excellent results and demonstrating much improved

strike characteristics. Although more expensive than

the previous electrodes, their life is significantly

longer which is expected to lead to long-term cost

savings. We are also aware of the health and safety

benefits of using non-thoriated electrodes." European

Manufacturing Facility.

"We have tested your MultiStrike® under production

conditions where we need to make short lengths welds

using the TIG process. On a batch of 50 components

only 2 light re-grinds were required compared to 7 heavy

regrinds when using thoriated electrodes. Even when the

welder occasionally touched the work with the electrode

there was no material change in performance whereas

we would normally expect to have to re-grind. Better weld

quality and finish was observed. We were particularly

impressed with the health and safety aspects and have

taken the decision to remove all thoriated electrodes from

site." Production Service Manager.

“We manufacture thin-walled hollow shaft products in type

316 stainless steel. Whereas with thoriated electrodes

we regularly encounter problems with weld pitting which

necessitates re-welding and often re-machining, this

has been virtually eliminated when using MultiStrike®.

Significant savings in the cost of post weld operations

have been observed.” Texas, USA.

"We have now had an opportunity to evaluate your

MultiStrike® Electrodes and can report extended

working life between re-grinds and improvement in

initial strike rates. The most significant improvement

however is in automatic machine use." Technical

Manager.

"We use computer controlled equipment for hot wire

cladding with stellite. With thoriated electrodes, we

observed rapid contamination leading to regrinding

after only 15/30 minutes. Using MultiStrike® has been a

revelation since we can achieve 8 hours of work between

regrinds. Savings in downtime have thus been significant."

Welding Engineer, Brighouse, UK.

You will prefer using Techweld® MultiStrike®

Tungsten Electrodes from

Huntingdon Fusion Techniques HFT®.

REPEATABLE STRIKES EVERYTIME........!