Dust Free Room for Titanium Welding

Conventionally the exotic material fabricators used to customise each and every tools to meet the critical requirement of purging and dust free enviornment which was huge in cost. Now we have come up with an unique solution which is a turnkey solution for such exotic material welding and at a econimical cost.

This includes all important features such as dust free room with proper insulation, Electical fittings, Flexible enclosure, special gas distribution arrangement on table, Gas Manifold system outside the cabin, dehumidifier, Air conditioner, Air curtain, Purge Monitor, Trailing Shield, Tungsten Grinder, Special SPM for holding and rotation of jobs inside the enclosure, Welding equipment with advanced features for exotic material welding.

We have supplied such turnkey solutions to many customers who have been serving aerospace industries. We have successfully done Installation and training Programme to User’s and Supervisors.

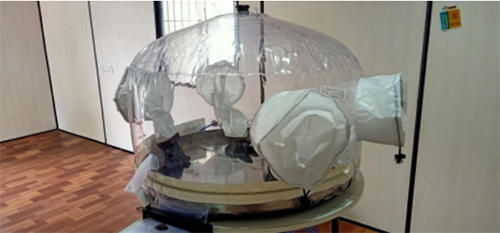

Dust Free Room Cabin

A lot of welders think titanium is difficult to weld, but really, like anything else, it takes knowledge and practice. Titanium is referred to as a reactive metal because it does not take kindly to contamination, and in fact, a contaminated Titanium weld can actually become brittle (something you definitely don’t want heading down a rough trail in a mountain bike).

Titanium is desirable because it is strong and lightweight, and resists corrosion, but the welder must take care to weld it correctly.

The first step to welding titanium is to make sure that the welding room is clean. You don’t necessarily need a hi- tech white clean room, and you won’t need to wear little paper booties, but the area where you will be welding should be as free of moisture, dust, grease and any other contaminants as you can attain. You’ll also want to be free of air drafts- turbulent air can draw in oxygen, which ruin your weld.

Some people use Flexible welding chamber which enclose your weld area.

Why Choose a Flexible Welding Closure?

For applications in which aesthetics count or X-Ray-quality welds are required, the reliability of this technology is vital. An inert atmosphere is a perfect environment for welding tungsten, titanium or any air sensitive material. Nowadays, a Flexible welding enclosure makes an educated choice to achieve optimum properties and surface finishes – for clean bright welds every time!

Rapid Pre-Welding Cycles

Whenever cleanliness is required, flexible welding enclosure is the solution. More specifically, a protective gas (Argon) shields the weld puddle from the atmosphere and protects the weld from contamination to secure corrosion resistance. And there's more: with faster and better pre-welding cycles, you can save in overall time and costs, by using our special arrangement of gas distribution on stainless steel work base plate which doesn’t allows to create air traps inside the enclosure and provide defect free titanium welding.

Ergonomic Work Area

Keep yourself safe is imperative. This is especially true when it comes to weld chambers. Buying appropriate equipment with generous, all-round visibility and well laid out controls is the first step for hassle-free work environment. Ergonomics means you can get work started straight away.

The Best Leakproof Tightness

To be acceptable to an industry as safety critical as aerospace, a number of performance criteria must be determined for welding process. For applications where leak-tightness is essential, enjoy using our welding flexible enclosures to meet all requirements and production rates.

Automatic Purging Cycles

Mistakes in gas purging lead to qualitatively unacceptable results. With our PURGE MONITOR instrument you can obtain stable and high speed performance, reducing your risks for weld defects. Be assured, your parts will be weld in perfect vacuum/inert atmosphere.

With leak-tight connectors for weld purge hoses, the PurgEye Nano can be used with optional accessory hand pump and gas sampling probe. It can be used to check purge gas quality from the main source and at the exhaust end of a purging system, as well as to find air leaks in purging hose connections anywhere in a system. The monitor can also be used to check the quality of the gas source to ensure that no contamination is present.

Airlock

To prevent any type of contamination and oxidation, our flexible welding enclosure are equipped with special clamping arrangement that allows loading and unloading of the material without emptying the whole system.

For video please click below youtube link https://www.youtube.com/watch?v=Y9DgCTrNQdc